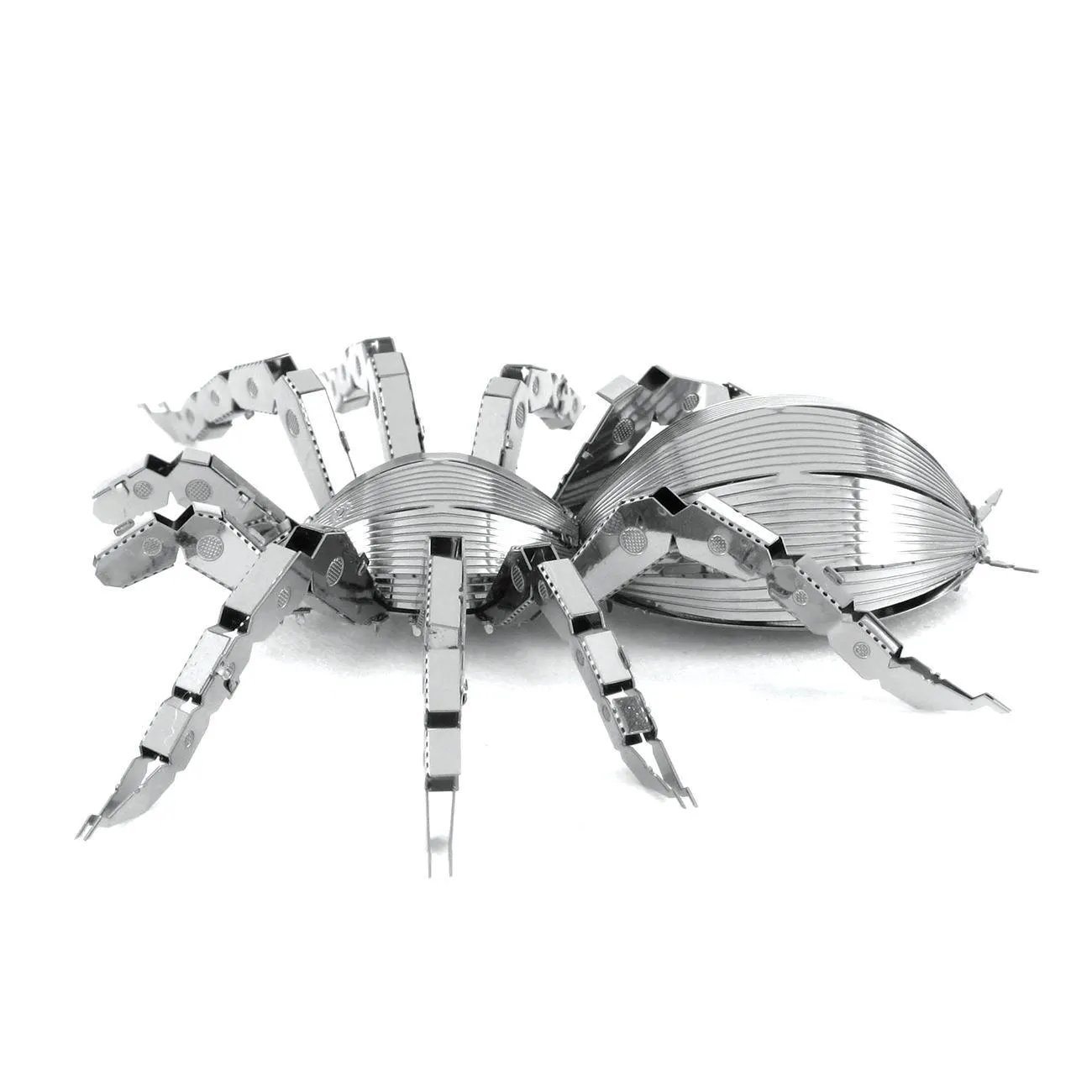

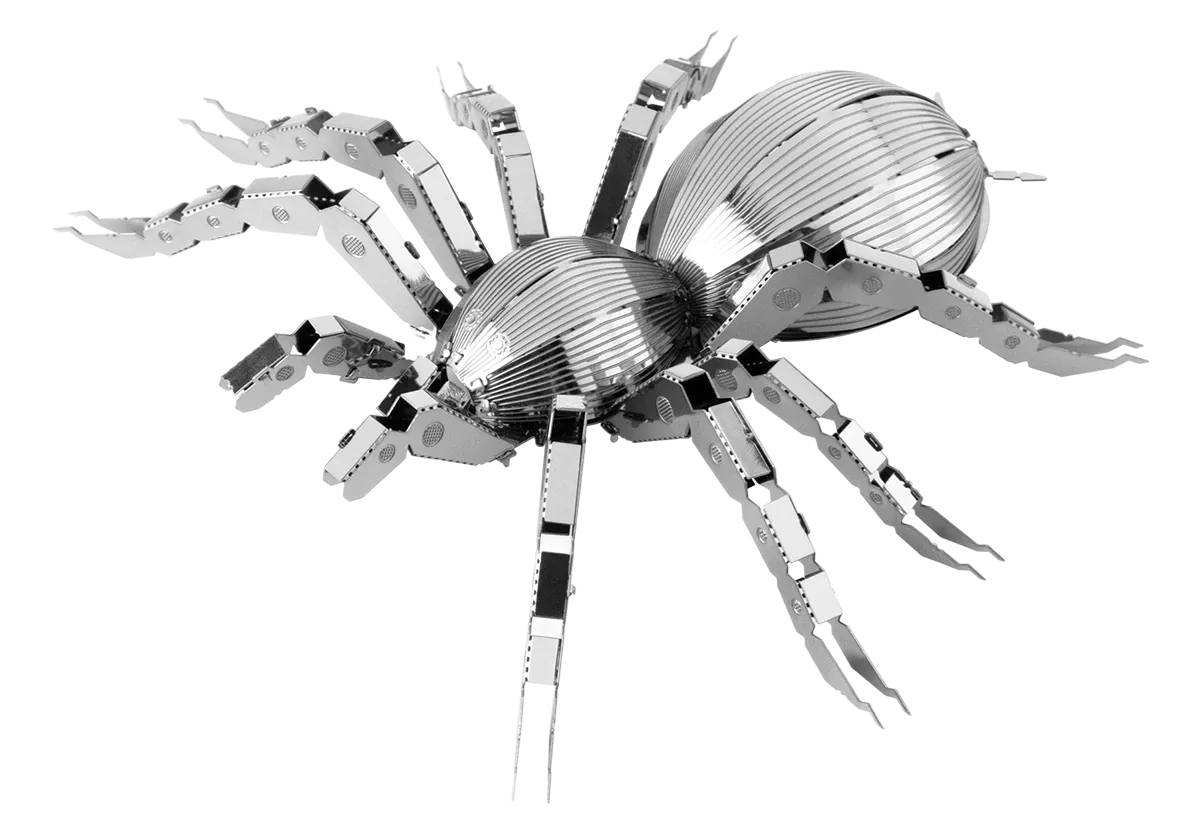

What is Tarantula Metal?

Tarantula Metal is a cutting-edge advanced material, rapidly gaining recognition across multiple industries for its unique combination of properties. This remarkable substance is not found naturally; it is meticulously engineered and manufactured, often involving complex processes to achieve its desired characteristics. The name is a metaphor, as its structure can be complex and intricate, much like the web of a tarantula. This innovative metal offers exceptional performance and versatility, setting it apart from traditional materials. Its unique composition and manufacturing methods allow for unprecedented applications in fields where extreme conditions and high precision are critical. The development of Tarantula Metal represents a significant leap forward in material science, providing engineers and designers with a powerful tool to overcome existing limitations and create innovative solutions.

Composition and Manufacturing

Key Elements

The composition of Tarantula Metal is highly customized, often involving a blend of various metals and alloys. The specific elements used can vary depending on the intended application, but common components may include titanium, aluminum, vanadium, and other specialty metals. The proportions of these elements are carefully controlled to achieve the desired balance of properties, such as strength, ductility, and resistance to corrosion. The selection of these elements is critical, as they influence the metal’s overall performance and suitability for different environments. Researchers and engineers are constantly exploring new combinations of elements to further enhance the metal’s capabilities and expand its potential applications, making it adaptable to a wide variety of needs.

Production Process

The manufacturing process for Tarantula Metal is equally important as its composition, often involving sophisticated techniques such as powder metallurgy, additive manufacturing (3D printing), and advanced casting methods. These techniques allow for precise control over the metal’s microstructure, leading to enhanced properties. For example, additive manufacturing can create complex shapes and geometries that would be impossible to achieve with traditional methods, opening up new possibilities in design and functionality. The manufacturing process is also critical for controlling the metal’s grain structure, which significantly impacts its strength and durability. These advanced production methods are essential to unlocking the full potential of Tarantula Metal, enabling its use in high-performance applications. Furthermore, these techniques enable the creation of unique material gradients and structures, further expanding the material’s capabilities.

Properties of Tarantula Metal

Strength and Durability

One of the most remarkable properties of Tarantula Metal is its exceptional strength-to-weight ratio, making it ideal for applications where minimizing weight is crucial. It can withstand extreme stresses and strains, providing superior durability compared to many conventional materials. This high strength allows engineers to design lighter and more efficient components without compromising structural integrity. The metal’s durability also extends to its resistance to fatigue and wear, ensuring a long service life even under demanding conditions. This combination of strength and durability makes Tarantula Metal particularly well-suited for industries where reliability and longevity are paramount, such as aerospace and automotive.

Corrosion Resistance

Tarantula Metal exhibits outstanding corrosion resistance, which is crucial for applications in harsh environments. It can withstand exposure to a wide range of corrosive substances, including acids, alkalis, and saltwater, without significant degradation. This property is often achieved through the careful selection of alloying elements and the formation of a protective surface layer. This resistance prevents the metal from weakening or failing prematurely, ensuring the longevity and reliability of components and structures. The corrosion resistance of Tarantula Metal makes it a valuable material for use in marine environments, chemical processing plants, and other applications where exposure to corrosive elements is unavoidable.

Thermal Conductivity

The thermal conductivity of Tarantula Metal can be tailored to suit specific applications. Depending on its composition and manufacturing, it can offer either excellent heat dissipation or effective thermal insulation. In applications where heat management is critical, such as in engine components, Tarantula Metal can quickly transfer heat away from critical areas, preventing overheating and ensuring optimal performance. Conversely, in applications requiring thermal insulation, such as in aerospace components, the metal can be designed to minimize heat transfer, protecting sensitive components from extreme temperatures. This versatility in thermal properties further enhances the adaptability of Tarantula Metal across a broad spectrum of industries and applications.

Applications of Tarantula Metal

Aerospace Industry

The aerospace industry is a major beneficiary of Tarantula Metal’s unique properties. Its high strength-to-weight ratio, coupled with its resistance to extreme temperatures and corrosion, makes it ideal for aircraft components, such as engine parts, structural elements, and even in the construction of spacecraft. The use of Tarantula Metal allows for lighter aircraft, resulting in improved fuel efficiency and reduced operating costs. Its durability and resistance to environmental factors also contribute to the safety and longevity of aircraft. Furthermore, the metal’s ability to withstand the stresses of high-speed flight and the harsh conditions of space makes it an indispensable material for the future of aerospace technology.

Automotive Industry

In the automotive industry, Tarantula Metal is used in the production of high-performance engine components, chassis parts, and lightweight body structures. Its strength and durability allow for the creation of safer and more efficient vehicles. The metal’s ability to withstand high temperatures and pressures makes it suitable for use in engines, while its lightweight nature contributes to improved fuel economy and handling. As the automotive industry moves towards electric vehicles, Tarantula Metal’s properties are becoming even more critical, as they can contribute to increased range and performance. The material’s versatility also allows for the creation of innovative designs and features, enhancing the overall driving experience.

Medical Implants

Tarantula Metal is finding increasing use in medical applications, particularly in the creation of implants and prosthetics. Its biocompatibility, strength, and corrosion resistance make it an excellent choice for these critical applications. The metal can be readily integrated into the human body without causing adverse reactions, and its durability ensures that implants can withstand the stresses of everyday life. The use of Tarantula Metal in medical devices can improve patient outcomes and quality of life. Moreover, the metal can be tailored to promote bone growth, allowing for more effective integration of implants within the body. These advancements in medical technology highlight the versatility and potential of Tarantula Metal.

Advantages of Using Tarantula Metal

Superior Performance

The primary advantage of Tarantula Metal lies in its superior performance characteristics. Its exceptional strength-to-weight ratio, combined with its resistance to corrosion, high temperatures, and wear, allows for the creation of components and structures that outperform those made from traditional materials. This leads to improved efficiency, increased durability, and enhanced safety in various applications. The ability to tailor the metal’s properties also allows for optimized designs that can meet specific performance requirements. This superior performance makes Tarantula Metal a material of choice for engineers and designers seeking to push the boundaries of innovation.

Long-Term Cost Efficiency

While the initial cost of Tarantula Metal may be higher than that of some conventional materials, its long-term cost efficiency often proves to be significantly greater. Its durability and resistance to corrosion and wear reduce the need for frequent replacements and maintenance, leading to lower lifecycle costs. In addition, the improved efficiency and performance enabled by Tarantula Metal can result in reduced operating costs, such as lower fuel consumption in aerospace applications. The long lifespan and reliability of components made from Tarantula Metal can also minimize downtime and associated expenses, making it a cost-effective solution in the long run.

Environmental Benefits

The use of Tarantula Metal can also contribute to environmental sustainability. Its lightweight nature can lead to reduced fuel consumption in transportation, resulting in lower greenhouse gas emissions. The durability of the metal extends the lifespan of products, reducing the need for frequent replacements and minimizing waste. Furthermore, the manufacturing processes for Tarantula Metal are constantly being refined to improve efficiency and reduce environmental impact. Research is also underway to develop eco-friendly methods of production, making it a more sustainable choice. These factors contribute to the overall positive environmental impact of Tarantula Metal, making it a viable option for environmentally conscious industries.

Challenges and Limitations

Cost of Production

One of the primary challenges associated with Tarantula Metal is its relatively high cost of production. The complex manufacturing processes and the use of specialized materials contribute to this higher cost. However, as technology advances and production methods improve, the cost of Tarantula Metal is expected to decrease, making it more accessible to a wider range of applications. Furthermore, the long-term cost benefits of its durability and performance can often offset the initial higher investment. Research and development efforts are focused on optimizing production techniques to reduce costs without compromising the metal’s exceptional properties.

Availability of Raw Materials

The availability of some of the raw materials used in Tarantula Metal can also pose a challenge. Some of the specialty metals used in its composition are relatively rare or require complex extraction and processing methods. This can impact the supply chain and potentially increase production costs. However, ongoing research focuses on discovering alternative materials and refining extraction techniques to ensure a stable supply of raw materials. Additionally, efforts are being made to recycle and reuse Tarantula Metal, further mitigating the impact of limited resource availability. The development of a sustainable supply chain is crucial for the long-term viability of this advanced material.

Future Developments and Research

New Alloys and Composites

Ongoing research and development efforts are focused on creating new alloys and composites based on Tarantula Metal. Scientists and engineers are constantly exploring different combinations of elements and manufacturing techniques to further enhance its properties. This includes developing new alloys with improved strength, corrosion resistance, and thermal conductivity. Additionally, research is being conducted on integrating Tarantula Metal with other advanced materials, such as carbon fiber composites, to create hybrid materials with even greater capabilities. These advancements are expected to expand the applications of Tarantula Metal and further solidify its position as a leading material in various industries.

Expanding Applications

The future of Tarantula Metal looks bright, with applications expected to expand into new and exciting areas. As research continues and production methods improve, it is likely to be adopted in a wider range of industries, including energy, construction, and consumer electronics. The development of new manufacturing techniques, such as large-scale 3D printing, will open up new possibilities for complex designs and geometries. Furthermore, as the cost of production decreases, Tarantula Metal will become more accessible to smaller businesses and research institutions. The ongoing innovation and exploration surrounding Tarantula Metal promise to revolutionize materials science and engineering for years to come.

Conclusion

Tarantula Metal represents a significant advancement in materials science, offering a unique combination of properties that make it ideal for a wide range of demanding applications. From its exceptional strength and corrosion resistance to its tailorable thermal properties, this advanced material is setting new standards for performance and efficiency. While challenges remain, particularly in terms of cost and raw material availability, ongoing research and development efforts are constantly expanding its capabilities and making it more accessible. As technology continues to evolve, Tarantula Metal is poised to play an increasingly important role in shaping the future of various industries, paving the way for groundbreaking innovations and sustainable solutions.