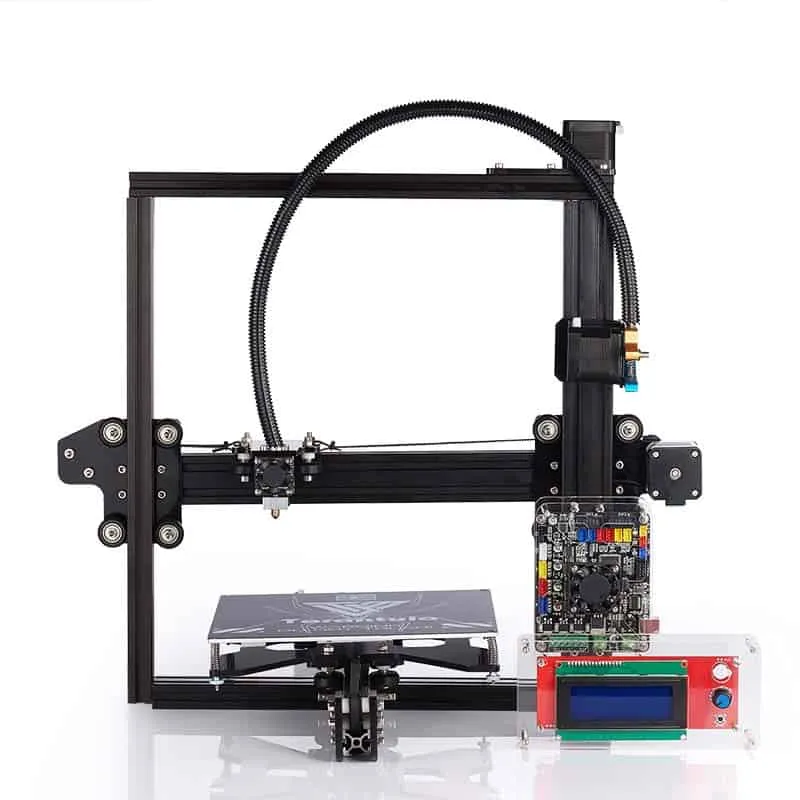

Tevo Tarantula Canada The Best 5 Tips

The Tevo Tarantula is a popular and affordable 3D printer, making it an excellent choice for hobbyists and those new to 3D printing in Canada. However, like any 3D printer, achieving high-quality prints requires understanding its nuances. This guide will provide you with the best 5 tips to maximize your Tevo Tarantula experience, ensuring you produce stunning 3D models with ease. From bed leveling to choosing the right filament and optimizing print settings, these tips will help you overcome common challenges and unlock the full potential of your Tevo Tarantula. Whether you’re a beginner or looking to refine your printing skills, this article is designed to help you succeed with your Tevo Tarantula in Canada.

Tip 1 Leveling the Bed for Perfect Prints

Bed leveling is the cornerstone of successful 3D printing. An uneven bed can lead to poor first-layer adhesion, warping, and failed prints. The Tevo Tarantula uses a manual bed leveling system, which requires careful adjustment of the bed’s screws. Regular and precise bed leveling is crucial for optimal print quality. Take your time to ensure the nozzle is at the correct distance from the bed across the entire print surface. Proper bed leveling ensures the initial layers adhere correctly, which is critical for the rest of the print. A well-leveled bed creates a solid foundation for your 3D models, preventing common issues and improving overall print quality.

Why Bed Leveling Matters

The importance of bed leveling cannot be overstated. It directly impacts the adhesion of the first layer, which in turn affects the entire print. If the nozzle is too far from the bed, the filament won’t stick, resulting in a messy, detached first layer. If the nozzle is too close, it can scrape the bed, potentially damaging the bed or the nozzle, and preventing the filament from extruding properly. A well-leveled bed ensures the filament adheres evenly across the entire surface, creating a solid foundation for your print. This is essential for preventing warping, poor layer adhesion, and other print failures. Investing time in proper bed leveling pays off with higher-quality prints and fewer failed attempts.

Tools and Techniques for Leveling

The Tevo Tarantula typically comes with basic leveling tools, but additional tools can enhance the process. A piece of paper is commonly used to gauge the distance between the nozzle and the bed. Move the nozzle to each corner of the bed and adjust the bed screws until the nozzle gently grips the paper. A feeler gauge can provide more precise measurements. Some users also opt for a bed leveling probe for more automated and precise leveling. Level the bed at each corner and the center. Repeat this process until the paper offers consistent resistance across the entire bed surface. Remember to preheat your bed to the printing temperature of your chosen filament for more accurate leveling, as the heat can slightly alter the bed’s dimensions. Be patient and methodical – accurate bed leveling is key to great prints.

Tip 2 Choosing the Right Filament

Selecting the right filament is crucial for achieving the desired results with your Tevo Tarantula. Different filaments have varying properties, making them suitable for different applications. Understanding these differences will help you choose the best filament for your projects. Consider the desired strength, flexibility, and temperature resistance of your 3D prints. Some filaments are easier to print with than others, while others require specific settings and precautions. The choice of filament significantly impacts the print quality, strength, and overall performance of your 3D-printed objects. Experimentation is key, but understanding the basic properties of each filament type will guide you toward making the right choice for your specific needs.

PLA vs ABS vs PETG Which is Best

PLA (Polylactic Acid) is a popular choice for beginners due to its ease of printing and low odor. It’s biodegradable and produces excellent print quality at lower temperatures. However, PLA is less heat-resistant and can warp in high-temperature environments. ABS (Acrylonitrile Butadiene Styrene) offers greater strength, durability, and temperature resistance, making it suitable for functional parts. However, ABS requires higher printing temperatures and a heated bed, and it can produce strong odors during printing. PETG (Polyethylene Terephthalate Glycol-modified) combines the best properties of both PLA and ABS. It’s easy to print like PLA, but it offers greater strength and temperature resistance than PLA. PETG is a versatile option for a wide range of applications. Each filament has pros and cons depending on the project at hand; understanding these properties helps in choosing the best one for each project.

Filament Storage & Handling

Proper filament storage and handling are essential to maintain print quality. Filaments are hygroscopic, meaning they absorb moisture from the air, which can lead to printing problems like stringing, bubbling, and poor layer adhesion. Store your filaments in a dry, airtight container, ideally with desiccant packets to absorb moisture. When not in use, keep filaments in a sealed bag or container. Avoid storing filaments in direct sunlight or high-humidity environments. Before printing, especially if the filament has been stored for a while, consider drying it in a filament dryer or your printer’s heated bed at a low temperature. Proper storage ensures your filament remains in optimal condition, preventing printing defects and enhancing the overall print quality. This will reduce the likelihood of print failures and help extend the life of your filament spools.

Tip 3 Optimizing Print Settings

Optimizing your print settings is essential for achieving the best results with your Tevo Tarantula. Print settings include various parameters, such as print speed, temperature, layer height, and infill. Experimenting with these settings can greatly improve print quality and print success rates. Each filament type requires different settings to print successfully. Start with the recommended settings for your chosen filament and printer model. Adjust these settings as needed to fine-tune your prints. The proper print settings ensure dimensional accuracy, reduce printing defects, and produce high-quality 3D-printed parts. Always refer to the filament manufacturer’s recommended settings as a starting point, and then adjust based on your printer and specific printing needs.

Slicer Software Overview

Slicer software converts 3D models into instructions for your 3D printer. Popular slicers include Cura, PrusaSlicer, and Simplify3D. Cura is a free and open-source slicer that’s widely used and offers a user-friendly interface. PrusaSlicer is another popular option, known for its advanced features and excellent print quality. Simplify3D is a premium slicer known for its advanced features and optimization capabilities. Each slicer has its own set of features and settings, so it’s important to choose one that suits your needs and skill level. Within the slicer, you can adjust settings such as layer height, print speed, temperature, and infill. Slicer software plays a crucial role in the 3D printing process and affects print quality, printing time, and material usage.

Adjusting Print Speed and Temperature

Print speed and temperature are two of the most critical settings to adjust. Print speed affects the printing time and print quality. Slower print speeds generally result in higher print quality but longer printing times. Higher print speeds can speed up the printing process but can lead to print defects like layer shifting or poor adhesion. Temperature significantly impacts the filament’s melting and extrusion. The correct temperature ensures the filament melts correctly, bonds to the previous layers, and produces a clean finish. Each filament has an ideal temperature range; refer to the filament’s specifications for recommended settings. Adjusting the temperature and print speed requires experimentation. Start with the recommended settings and make small adjustments to achieve the best results for your specific filament and printer.

Tip 4 Upgrading Your Tevo Tarantula

Upgrading your Tevo Tarantula can significantly improve its performance, reliability, and print quality. There is a wide variety of upgrades available for the Tevo Tarantula, from simple enhancements to more advanced modifications. Upgrading your 3D printer can address common issues, improve print quality, and provide a more enjoyable user experience. Upgrades can be customized to specific needs and budget constraints. By carefully selecting upgrades, you can transform your Tevo Tarantula into a high-performing 3D printing machine. Assess your printing needs and choose upgrades that will provide the most benefit.

Common Upgrades to Consider

Popular upgrades include a glass or PEI bed surface for better adhesion and easier part removal, a new extruder for improved filament feeding, and a heated bed. Replacing the stock hotend with an all-metal hotend can allow you to print at higher temperatures, enabling the use of a wider range of filaments. Consider a more stable frame or adding frame stiffeners to improve the printer’s rigidity and reduce vibrations. Installing a silent mainboard can dramatically reduce the noise generated by the printer. A BLTouch or other auto-bed leveling system can simplify bed leveling and improve the consistency of your prints. Evaluate your current printing experience and determine which upgrades can address your most pressing issues.

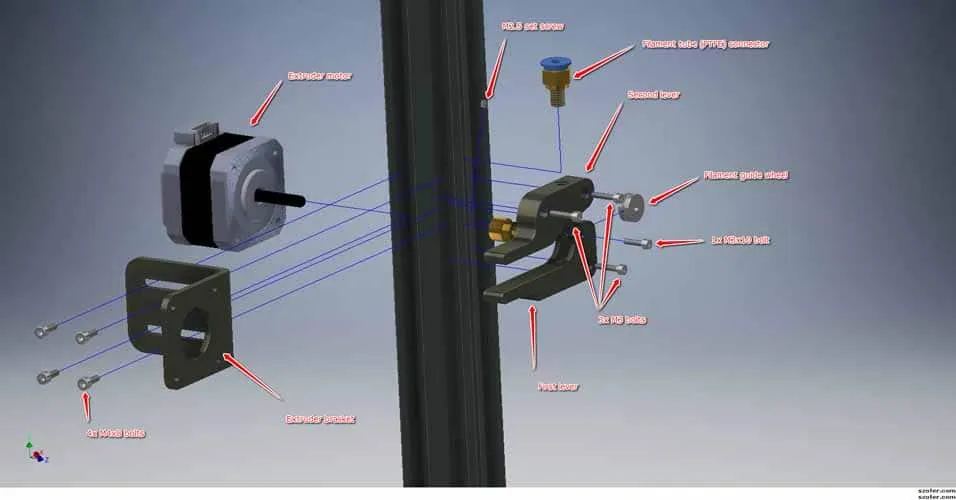

Installing Upgrades

Installing upgrades often requires basic technical skills and familiarity with the Tevo Tarantula’s components. Before starting, consult online resources, such as videos and forums. Carefully follow the instructions for each upgrade. Always disconnect the printer from the power supply before performing any electrical modifications. Take photos before disassembling the printer to help with reassembly. Test the printer after installing each upgrade to ensure it functions correctly. If you’re not comfortable performing the installation yourself, consider seeking assistance from a more experienced 3D printing enthusiast. Proper installation is crucial to ensure upgrades function correctly and enhance the printer’s performance and reliability.

Tip 5 Troubleshooting Common Issues

3D printing involves occasional troubleshooting. Knowing how to diagnose and fix common issues will save you time and frustration. Common problems include bed adhesion issues, nozzle clogging, and layer shifting. Addressing these issues promptly can prevent print failures and maintain print quality. Keep in mind that troubleshooting is an ongoing process, and the more experience you gain with your Tevo Tarantula, the better you’ll become at identifying and resolving print problems. Have a troubleshooting checklist ready to diagnose issues efficiently. By understanding and addressing common issues, you can improve print quality and get the most out of your 3D printer.

Dealing with Warping and Layer Adhesion

Warping and poor layer adhesion are common issues. Warping occurs when the print curls up from the bed, often due to uneven cooling or poor bed adhesion. Ensure your bed is properly leveled and clean. Use a heated bed to help the first layer stick. Applying an adhesive like glue stick or hairspray can improve adhesion. Poor layer adhesion results in weak parts. This may occur if the nozzle temperature is too low or the print speed is too fast. Increase the nozzle temperature slightly and slow down the print speed to improve layer bonding. Using a brim or raft can also help with bed adhesion. Optimizing these settings and techniques will minimize these issues.

Nozzle Clogging and Filament Issues

Nozzle clogging and filament issues are another common source of problems. Nozzle clogging can occur if the filament is too old, or if the nozzle temperature is too low. The nozzle can also clog if the printer is not maintained regularly. Clean the nozzle with a needle or by performing a cold pull to remove obstructions. Filament issues include uneven extrusion, under-extrusion, and stringing. Uneven extrusion may be caused by the nozzle being partially clogged or by the filament being tangled on the spool. Adjust the filament temperature, print speed, or the retraction settings in your slicer software to resolve these issues. Stringing can be caused by the nozzle temperature being too high, or by the retraction settings not being correct.