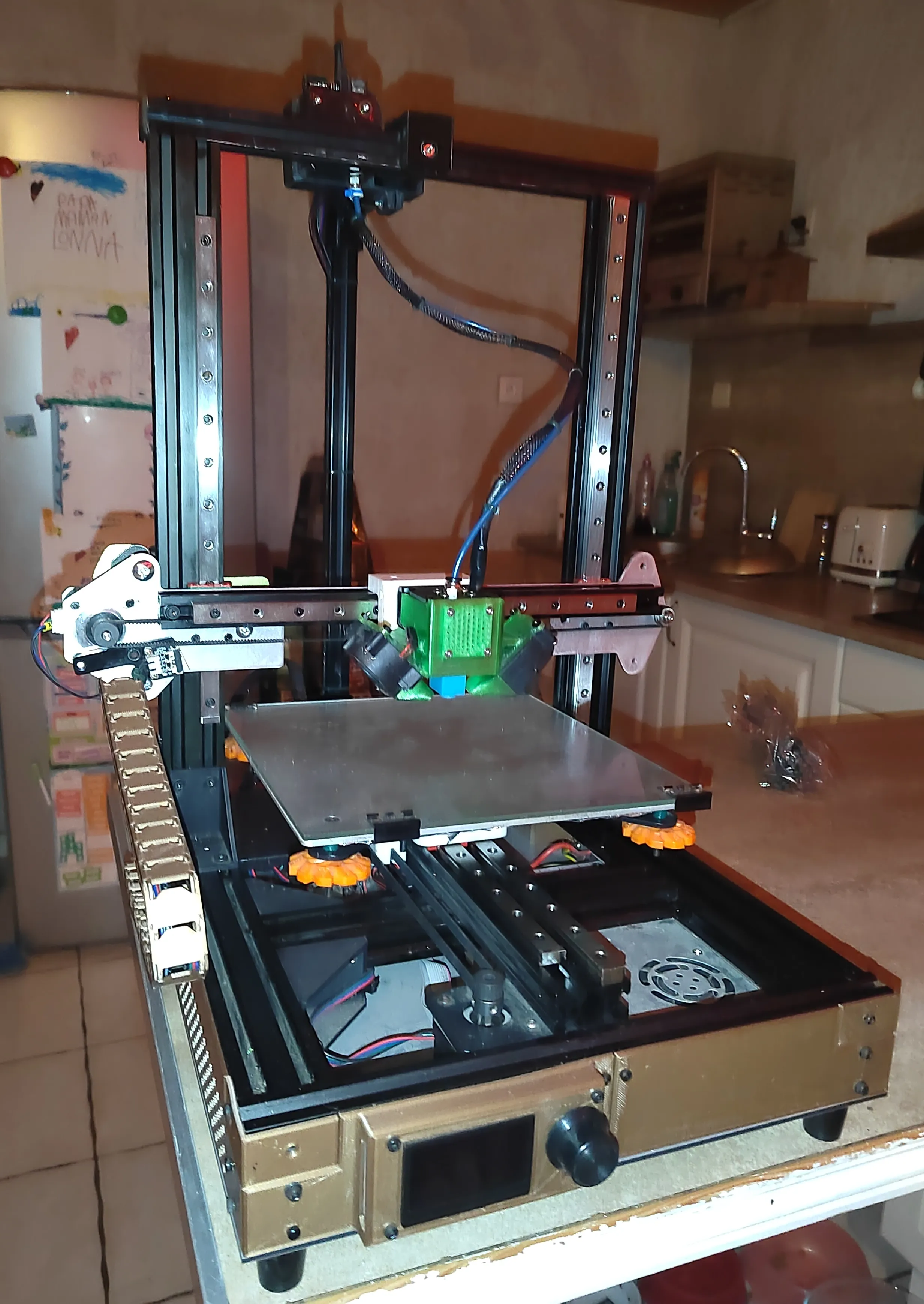

Tevo Tarantula Pro Brazil Tips for Beginners

The Tevo Tarantula Pro is a popular 3D printer, and in Brazil, its affordability and capabilities make it a favorite among hobbyists and enthusiasts. However, getting started can be a bit daunting. This guide provides five essential tips to help beginners in Brazil get the most out of their Tevo Tarantula Pro. From bed leveling to choosing the right filament and optimizing settings, these insights will improve your printing experience and ensure successful prints. With a little know-how, you can unlock the full potential of your 3D printer and bring your ideas to life. Let’s dive into the essential tips to get you printing successfully in Brazil’s unique climate and conditions.

Leveling the Bed Correctly

One of the most critical steps for successful 3D printing with your Tevo Tarantula Pro is bed leveling. A properly leveled bed ensures that the first layer adheres correctly, which is essential for the entire print to succeed. This is especially important in Brazil, where temperature and humidity can fluctuate, potentially impacting bed adhesion. Take the time to level your bed meticulously before each print, as this will save you a lot of frustration and wasted filament. Proper bed leveling provides a solid foundation for all your 3D printing projects, whether you are printing a small toy or a complex engineering model. A well-leveled bed is the cornerstone of quality 3D printing.

Bed Leveling Steps

To level the bed, start by ensuring the bed and nozzle are clean. Heat the bed to the appropriate temperature for your filament. Then, using the printer’s control panel or software, move the nozzle to each corner of the bed. At each corner, adjust the bed leveling screws (usually found under the bed) until the nozzle lightly grazes the bed. You can use a piece of paper to gauge the distance. It should have slight resistance as you move it between the nozzle and the bed. Repeat this process several times until the bed is level across all corners. The process might need to be adjusted based on the specific filament you are using, and always double-check the level before starting any print. Consistent bed leveling is critical for a smooth and successful printing experience.

Troubleshooting Bed Adhesion Issues

If you’re experiencing bed adhesion problems, several factors could be at play. First, make sure the bed is clean. Use isopropyl alcohol to wipe it down before each print to remove any oils or debris. Adjust your nozzle height, ensuring it’s not too far from the bed. This adjustment can make a huge difference for proper adhesion. You can also use adhesive aids like glue sticks or specialized bed adhesives. For PETG or other materials, a heated bed is essential. The temperature must be suited for the type of material. If the problem continues, verify that your bed leveling is precise, and consider using a brim or raft in your slicing software, which provides extra surface area for the print to stick to the bed, improving the chance of success.

Choosing the Right Filament

Selecting the correct filament is vital for quality prints, and the choice depends on your project’s requirements. In Brazil’s climate, you should consider the humidity levels, which can impact the filament’s performance. PLA (Polylactic Acid) is a popular choice for beginners due to its ease of use and low odor. However, it is sensitive to heat and humidity, so proper storage in a dry environment is important if you are not printing constantly. ABS (Acrylonitrile Butadiene Styrene) is a more durable option, but it requires a heated bed and enclosed environment. Other options include PETG (Polyethylene Terephthalate Glycol), which offers a good balance of strength and ease of printing. Experimenting with different filaments will help you determine which one suits your needs best.

PLA Filament for Brazil Climate

PLA is a user-friendly filament suitable for many projects in Brazil. It’s biodegradable and produces minimal odor during printing. However, the high humidity levels that can be present in certain parts of Brazil can affect PLA. To prevent this, store PLA in a dry box or sealed container with desiccant packs. When printing, use a heated bed (usually 50-60°C) for improved bed adhesion, especially in humid conditions. Ensure that the filament is stored in a dry place and used soon after opening. This will ensure better print quality and prevent common issues like warping or poor layer adhesion. By following these precautions, you can enjoy the benefits of PLA for your 3D printing projects in Brazil.

ABS Filament Considerations

ABS is a durable filament often used for parts that need to withstand higher temperatures or stress. However, printing ABS can be more challenging. It requires a heated bed (around 90-110°C) and, ideally, an enclosure to maintain a consistent temperature and prevent warping. This is extremely important in Brazil where temperature and humidity fluctuate. Poor ventilation can lead to warping. When printing ABS, ensure proper ventilation to eliminate fumes, which can be harmful. It’s advisable to print ABS in a well-ventilated area. If you are looking for strong, heat-resistant parts, ABS is a great choice, but be prepared to manage its specific requirements to achieve the best results.

Optimizing Print Settings

Fine-tuning your print settings is essential for achieving high-quality prints with your Tevo Tarantula Pro. Several key parameters can significantly affect the outcome of your prints. These include temperature, print speed, and layer height. Experimenting with these settings will allow you to find the optimal configuration for different filaments and project requirements. Always start with the manufacturer’s recommended settings for your filament and make small adjustments to achieve the desired results. Proper print settings allow you to make the best use of the capabilities of your Tevo Tarantula Pro, giving you prints that are as close to perfect as possible.

Temperature Settings

The temperature settings for your nozzle and bed are critical for successful printing. The optimal nozzle temperature depends on the filament you are using; PLA typically prints between 190-220°C, while ABS requires higher temperatures, usually 230-250°C. Using the correct temperature provides sufficient melting and flow of the filament. The bed temperature also depends on the filament type, often requiring a heated bed. Adjust temperatures in small increments, observing how the filament flows and how the layers adhere. If the temperature is too low, the filament may not adhere to the bed or other layers. If it is too high, you may see issues like oozing or stringing. Temperature adjustments will ensure your prints are strong and have precise details.

Print Speed Adjustment

Print speed impacts print quality and time. A faster speed can reduce printing time, but it may also result in lower quality. For PLA, a print speed of 40-60 mm/s is generally a good starting point, while for ABS, you may want to reduce the speed to 30-40 mm/s to ensure proper layer adhesion. Adjust print speeds based on the complexity of the model. For intricate designs, a slower speed will provide more detail. Experimenting with print speeds allows you to find the best balance between speed and quality for each of your 3D printing projects. Slowing the printing speed can increase print quality, but it also increases the printing time. Therefore, finding the right balance depends on your specific needs and priorities.

Improving Print Quality

To further enhance the quality of your prints, focus on calibration and adjustments. Calibrating your extruder, adjusting belts and pulleys, and ensuring that your printer is mechanically sound are important steps. Properly calibrating and maintaining the printer will produce consistent and accurate prints. In Brazil, where environmental factors can play a role, keeping your printer well-maintained will help it withstand the challenges of temperature fluctuations and humidity changes. Regular maintenance and calibration will ensure that your Tevo Tarantula Pro continues to deliver excellent results. Taking a proactive approach will lead to prints with better details, cleaner lines, and more accurate dimensions.

Calibrating the Extruder

The extruder feeds filament into the hot end, and proper calibration is important for consistent prints. The extruder needs to push the right amount of filament. Calibrate your extruder by measuring how much filament it extrudes over a set distance. You can then adjust the E-steps per millimeter setting in your printer’s firmware. This ensures that the printer extrudes the correct amount of filament for each layer. Calibration should be performed with the filament you intend to use, as the material’s properties can influence the extrusion process. Precise extrusion leads to better layer adhesion and overall print quality, and can help to avoid issues such as under-extrusion or over-extrusion. Regularly calibrating your extruder is an essential part of good 3D printing practice.

Adjusting Belts and Pulleys

Loose belts and pulleys can cause print quality issues like layer shifting and inaccurate dimensions. Ensure all belts are taut but not overly tight. You can tighten the belts by adjusting the screws on the belt tensioners. Check the pulleys for any play and ensure that they are firmly secured. If the belts are too loose, the print head may not move precisely, leading to misaligned layers and defects. Properly tensioned belts will minimize these issues and produce more accurate and higher-quality prints. Regular checks and adjustments of the belts and pulleys are a key part of maintaining your printer. You will achieve better results if the printer is mechanically sound.

Maintaining Your Tevo Tarantula Pro

Consistent maintenance will extend the lifespan of your Tevo Tarantula Pro. Regular cleaning, lubricating moving parts, and storing the printer in a suitable environment are key practices. Proper maintenance will not only keep your printer running smoothly but also ensure the quality of your prints. Take the time to maintain your printer, and you will get the best possible results. In Brazil, the high humidity and the warm climate can contribute to premature wear and tear of the printer’s components. Thus, maintenance becomes even more important in such conditions. This maintenance ensures reliable and successful prints, reducing the need for troubleshooting.

Regular Cleaning and Maintenance

Regularly clean your Tevo Tarantula Pro to remove dust, debris, and filament residue. Use a soft brush or compressed air to clean the hot end, bed, and other components. Remove any filament bits that may have accumulated. Check and tighten screws, and inspect the wiring for any damage. Clean the nozzle to ensure clear filament extrusion. Consider taking your printer apart regularly, checking and cleaning the components. Keep your printer in a clean environment, ideally, with low humidity, to prevent corrosion or other environmental damage. Cleaning and maintenance will prevent future issues and keep your printer in good working order. It helps ensure that your printer operates smoothly.

Lubricating Moving Parts

Lubricate the moving parts of your Tevo Tarantula Pro to reduce friction and wear. Use a suitable lubricant, such as lithium grease or machine oil, on the Z-axis rods, linear bearings, and other moving parts. Lubricating these parts will make your printer operate more smoothly and quietly. Lubrication can extend the life of the components and improve print quality. Avoid over-lubrication, as this can attract dust and debris, which can cause issues. Applying lubrication, in appropriate amounts, will allow your printer to run more efficiently. Regular maintenance will reduce wear and tear. Follow the manufacturer’s recommendations regarding the type and frequency of lubrication. By keeping all the moving parts lubricated, your printer is more likely to provide long-term and reliable performance.