Understanding the Tevo Tarantula RS Manual

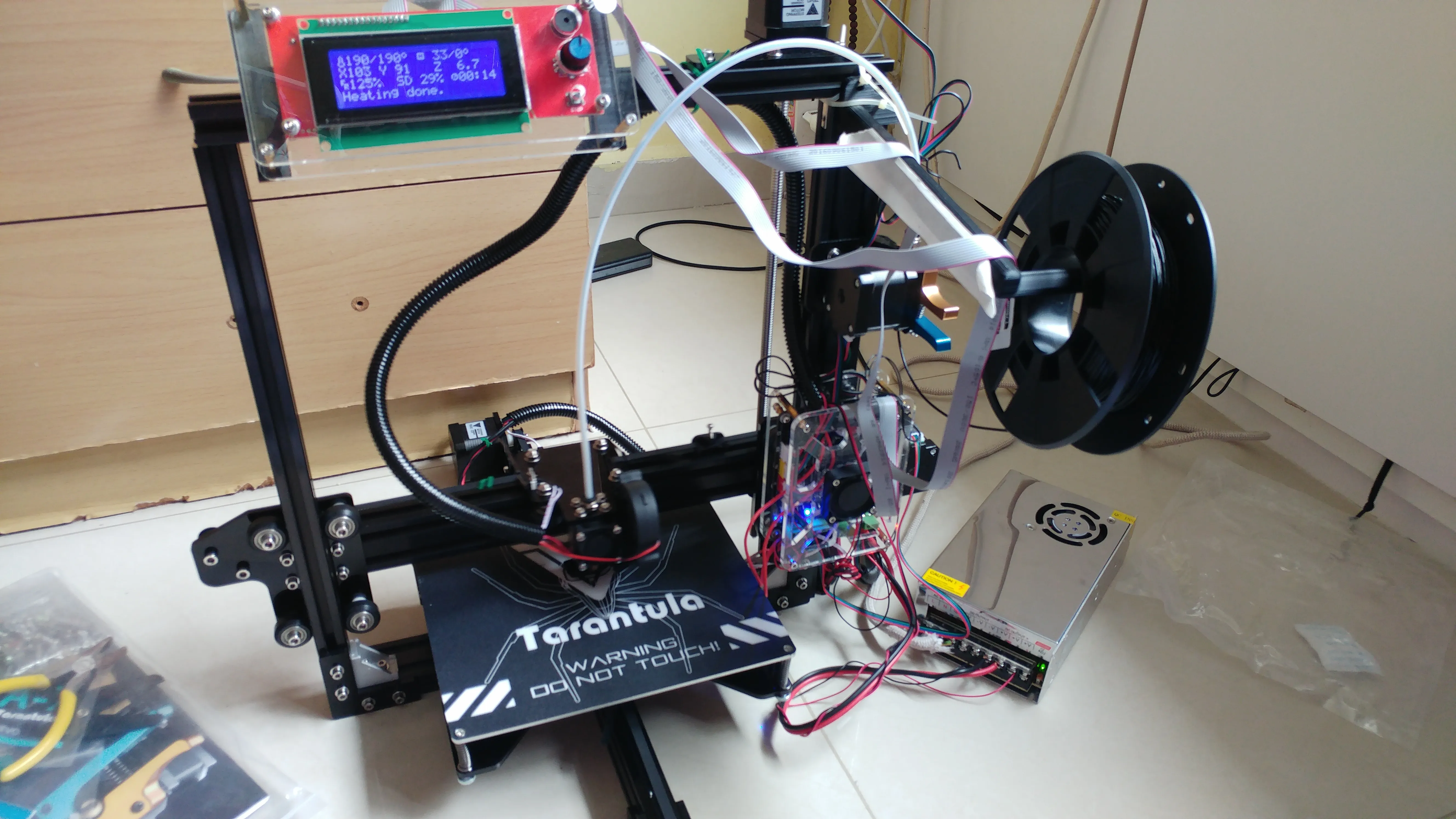

The Tevo Tarantula RS is a popular DIY 3D printer, and a comprehensive manual is essential for successful operation. This manual serves as your primary guide, providing detailed instructions for assembly, operation, and maintenance. It’s the key to unlocking the full potential of your 3D printer. Familiarizing yourself with the manual is the first and most critical step. It ensures you understand the printer’s components, how they work together, and how to troubleshoot any issues that may arise. Think of the manual as your personal trainer for 3D printing. It will guide you through the basics and help you master the intricacies of creating three-dimensional objects.

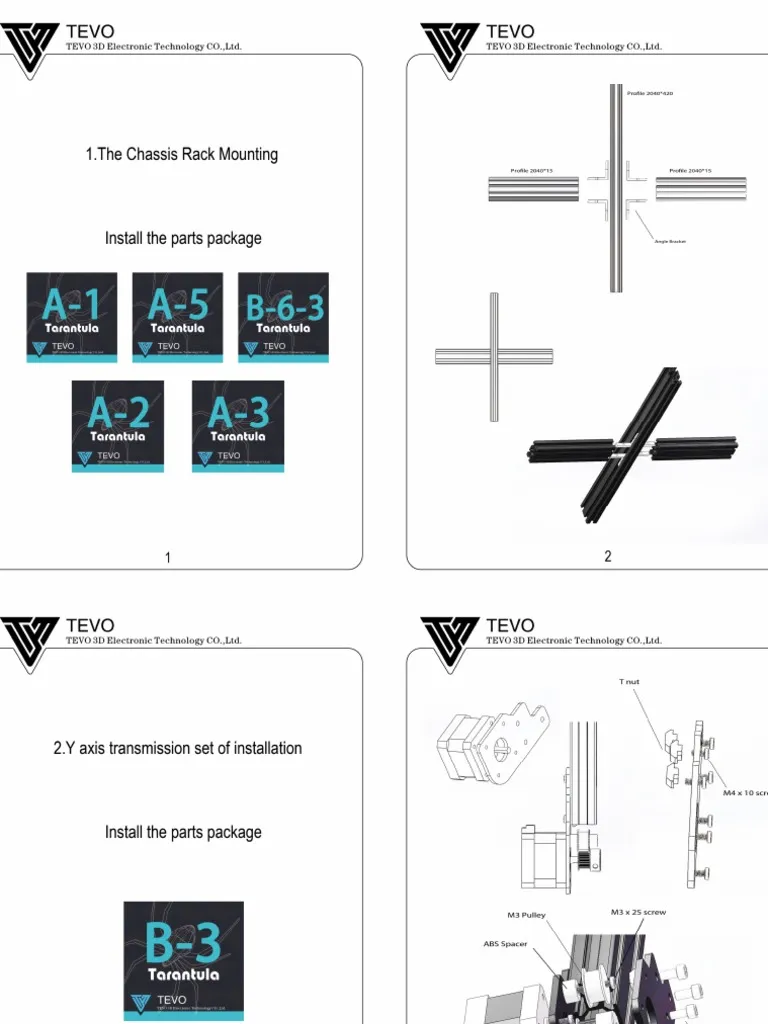

What’s Included in the Tevo Tarantula RS Manual

The Tevo Tarantula RS manual typically includes everything you need to get started. This includes a detailed parts list, assembly instructions with accompanying diagrams, and step-by-step guides for calibrating and operating the printer. Furthermore, the manual often provides information on slicing software, recommended print settings for various materials, and troubleshooting tips. The illustrations within the manual are crucial, as they visually represent the assembly process, helping you to correctly identify and connect all the necessary components. Make sure to keep your manual handy, as it’s the best resource when problems occur.

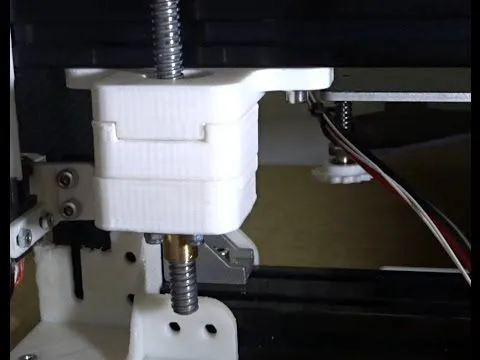

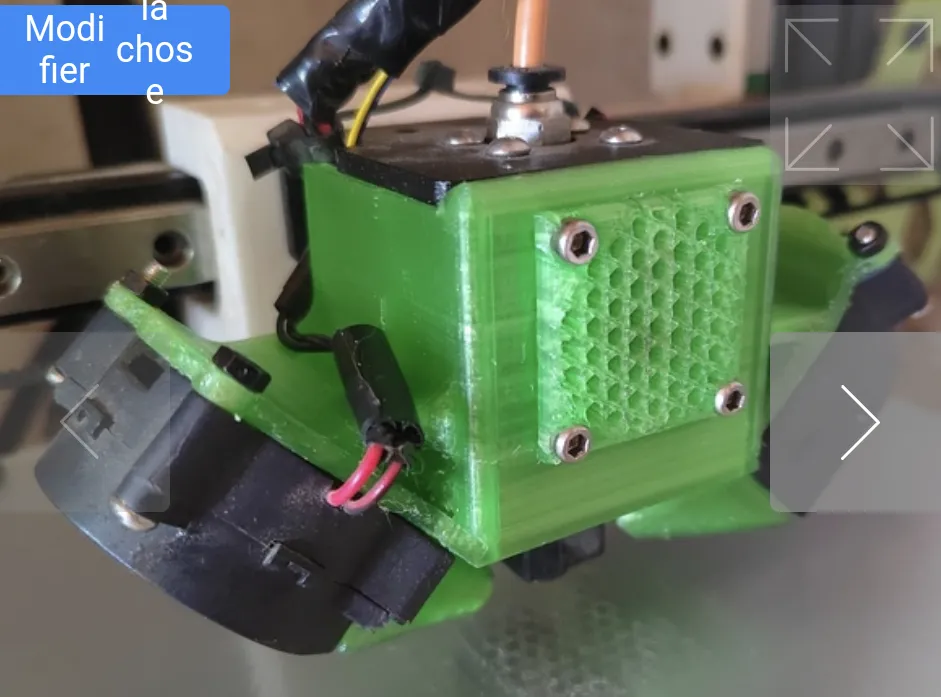

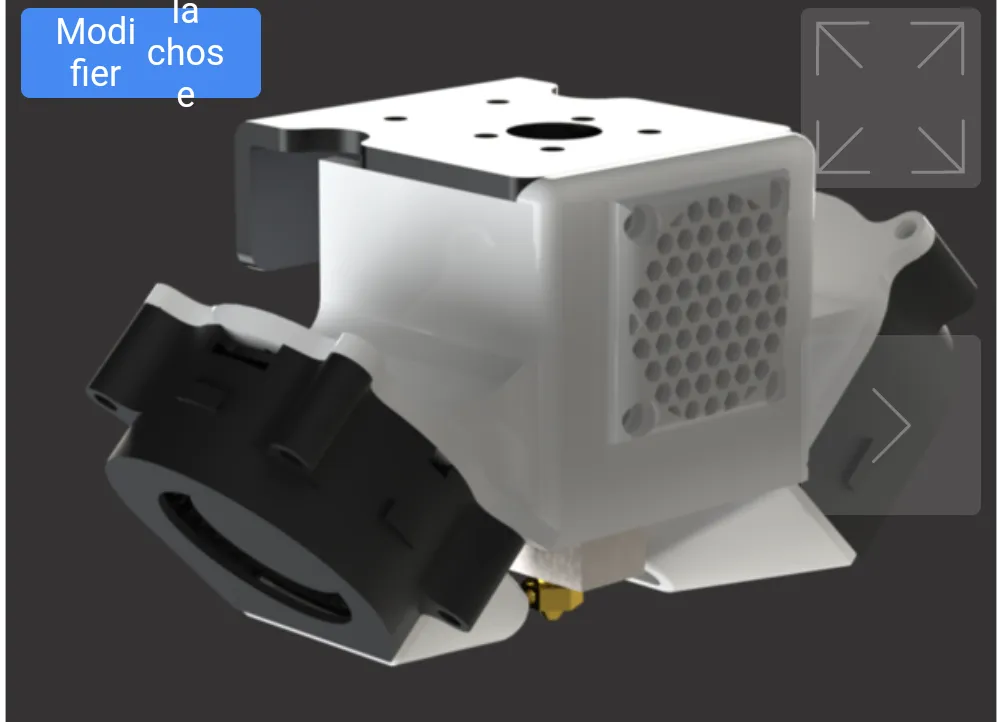

Key Components and Their Functions

Before you begin printing, it’s important to understand the essential components of the Tevo Tarantula RS. The frame provides the structural support for the printer. The heated bed, where your prints adhere, requires proper calibration. The extruder melts and deposits the filament onto the bed. The hotend heats the filament, enabling it to be extruded. The stepper motors control the movement of the print head and the bed. The control board manages all these functions, coordinating the movements and heating elements. The power supply provides the necessary electricity. Understanding the function of these components will greatly help you understand the overall functionality of your 3D printer.

Top 5 Tips for Using Your Tevo Tarantula RS

Now, let’s dive into the top 5 tips that will help you get the most out of your Tevo Tarantula RS 3D printer. These tips cover essential aspects of 3D printing, from initial setup to ongoing maintenance, ensuring a smooth and enjoyable printing experience. Follow these tips to maximize the success rate of your prints and to improve the overall quality of your models. Learning these tips will reduce frustration and increase the reliability of your 3D printer.

Tip 1 Leveling the Print Bed

Proper bed leveling is the cornerstone of successful 3D printing. An uneven bed can lead to poor first-layer adhesion, warped prints, and other print failures. This is the most critical step that directly impacts the quality of your prints. If the bed is too close to the nozzle, the filament won’t extrude properly, and if it’s too far, the filament won’t stick. Correct leveling ensures the perfect distance for the first layer. You can use the manual leveling process that comes with the printer, or you can upgrade the machine with an auto-bed leveling system for more convenience. This is the most common issue that new users struggle with. Take your time and be patient, it is worth the effort.

Why Bed Leveling is Crucial

Bed leveling ensures that the initial layer of filament adheres properly to the print bed. This first layer forms the foundation of your print, and any imperfections here will be magnified throughout the print. This will impact the entire print process, and can lead to failed prints and wasted filament. Properly leveled beds provide a stable surface for your model, prevent warping, and ensures accurate dimensions. Taking the time to level the bed carefully significantly reduces the chances of failed prints.

Step-by-step Guide to Leveling

Consult your manual for the specific leveling procedure for your Tevo Tarantula RS. In general, the process involves adjusting the bed height at each corner using leveling screws. The goal is to ensure a consistent gap between the nozzle and the bed across the entire print surface. Often, using a piece of paper to feel the distance between the nozzle and the bed is the easiest way to measure this gap. Slowly adjust the bed at each corner until you feel slight resistance when sliding the paper between the nozzle and the bed. Repeat this process several times, making small adjustments until the bed is perfectly level.

Tip 2 Setting Up Your Slicer Software

Slicer software is essential for converting 3D models into instructions that your 3D printer can understand. Popular slicer software options include Cura, PrusaSlicer, and Simplify3D. You must configure the settings in the slicer software to match your specific 3D printer and filament type. Incorrect settings can lead to print failures or poor print quality. The settings you choose will affect the print speed, temperatures, infill density, and other print parameters. Experimenting with these settings is part of the fun of 3D printing, allowing you to optimize prints for specific purposes. Most importantly, your slicer software must be set up correctly for your printer.

Recommended Slicer Settings

The Tevo Tarantula RS manual will often provide recommended slicer settings. These may include nozzle temperature, bed temperature, print speed, and layer height. Start with these recommended settings and then adjust them based on the specific filament you are using. Filament material is key, and will change the best settings for your 3D prints. For example, PLA generally prints at a lower temperature than ABS. The layer height will impact the level of detail in your prints. Using these recommended settings will give you the perfect starting point to fine tune your 3D prints.

Troubleshooting Slicer Issues

If you encounter problems with your prints, the slicer settings are often the first place to look. Common issues include poor adhesion, stringing, and warping. If the first layer doesn’t stick, try lowering the print speed or increasing the bed temperature. Stringing can be resolved by adjusting the retraction settings. Warping can be caused by a bed that is too cold. Experimenting with different settings and looking at the output in the slicer preview mode can help to solve many common issues. Online 3D printing communities are great for troubleshooting when you are stuck.

Tip 3 Filament Selection and Management

Choosing the right filament is crucial for the success of your 3D prints. The type of filament you choose will affect the print quality, strength, and durability of your printed parts. PLA (Polylactic Acid) is a beginner-friendly filament known for its ease of use and low odor. ABS (Acrylonitrile Butadiene Styrene) is a more durable option, but it requires a heated bed and a well-ventilated area due to its fumes. Other popular options include PETG, TPU (Thermoplastic Polyurethane), and specialized filaments like carbon fiber-filled filaments. Make sure you pick the correct filament for your project. You must also manage the filament after it is opened.

Choosing the Right Filament

Consider the properties of different filaments when making your choice. PLA is ideal for general-purpose prints, while ABS is better suited for parts that need to withstand higher temperatures or stresses. PETG offers a good balance of strength and ease of printing. TPU is flexible and is great for printing items such as phone cases or flexible parts. Carbon fiber-filled filaments provide increased strength and rigidity. Read reviews and consult online communities to get recommendations for filament brands and types. Select your filament according to the purpose of the part you are printing.

Filament Storage Best Practices

Filament is hygroscopic, meaning it absorbs moisture from the air. This can lead to print quality issues, such as bubbles and poor layer adhesion. Store your filament in a dry, airtight container when not in use. Consider using silica gel packets to absorb any moisture. If your filament has absorbed moisture, you can dry it using a filament dryer or by placing it in an oven at a low temperature. Correct filament storage ensures that your prints are perfect every time. These small steps can make a large difference in the quality of your 3D prints.

Tip 4 Optimizing Print Settings for Quality

Fine-tuning your print settings is key to achieving high-quality prints. This involves adjusting parameters like print speed, temperature, layer height, and infill density. These settings directly influence the appearance, strength, and accuracy of your printed parts. Small adjustments can result in major improvements to the quality of your final prints. Learning how to adjust these settings allows you to take your 3D printing skills to the next level.

Adjusting Print Speed and Temperature

Print speed and temperature are two of the most important settings to optimize. Printing too fast can lead to layer separation and poor surface finish. Start with the recommended print speed for your filament and gradually increase it until you see quality issues. The nozzle temperature affects the filament’s ability to melt and flow smoothly. If the temperature is too low, the filament may not extrude properly. If the temperature is too high, the filament may ooze or string. Finding the optimal temperature range is key to achieving the best results. Experimentation is key!

Addressing Common Print Defects

Many print defects can be addressed by adjusting your print settings. Stringing can be reduced by increasing the retraction settings and lowering the print temperature. Warping can be addressed by ensuring the bed temperature is correct and using a brim or raft. Poor layer adhesion can be improved by increasing the nozzle temperature or reducing the print speed. Over-extrusion is common and can be resolved by calibrating your extruder steps per millimeter (E-steps) or reducing the flow rate. Use online 3D printing communities to get more specific solutions.

Tip 5 Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential for keeping your Tevo Tarantula RS running smoothly. This involves periodic checks, cleaning, and adjustments to ensure the printer operates at its best. Regular maintenance will extend the life of your 3D printer and prevent unexpected breakdowns. This is a key part of 3D printing. These efforts pay off over time with reliable prints.

Regular Maintenance Tasks

Regular maintenance tasks include cleaning the print bed, lubricating moving parts, and checking the belt tension. Clean the print bed before each print to ensure good adhesion. Lubricate the lead screws and smooth rods to reduce friction and wear. Check the belt tension and tighten as needed to prevent print quality issues. Performing these tasks will reduce print failures. Refer to your Tevo Tarantula RS manual for the specific maintenance schedule recommended by the manufacturer. The more you care for your printer, the longer it will last.

Common Problems and Solutions

Familiarize yourself with common 3D printing problems and their solutions. Clogged nozzles are common, and can be cleared using a needle or by performing a cold pull. Belt slippage can lead to inaccurate prints and can be fixed by tightening the belts. Layer shifting can be caused by loose belts or a malfunctioning stepper motor, and this may also require replacing the motor. Online resources, like forums and communities, can provide a wealth of troubleshooting information. Don’t be afraid to ask for help from the 3D printing community.

Where to Find More Resources

Beyond the Tevo Tarantula RS manual, many online resources can help you with 3D printing. The internet is full of information that can help you learn the intricacies of your 3D printer and printing in general. Online forums and communities dedicated to 3D printing offer a wealth of information and support, and they are great places to ask for help. YouTube channels and tutorials provide visual guides and demonstrations of various 3D printing techniques. These resources are valuable for both beginners and experienced users. Don’t hesitate to seek help if you have any problems. The 3D printing community is a friendly and helpful group.