Understanding Tevo Tarantula Acceleration Settings

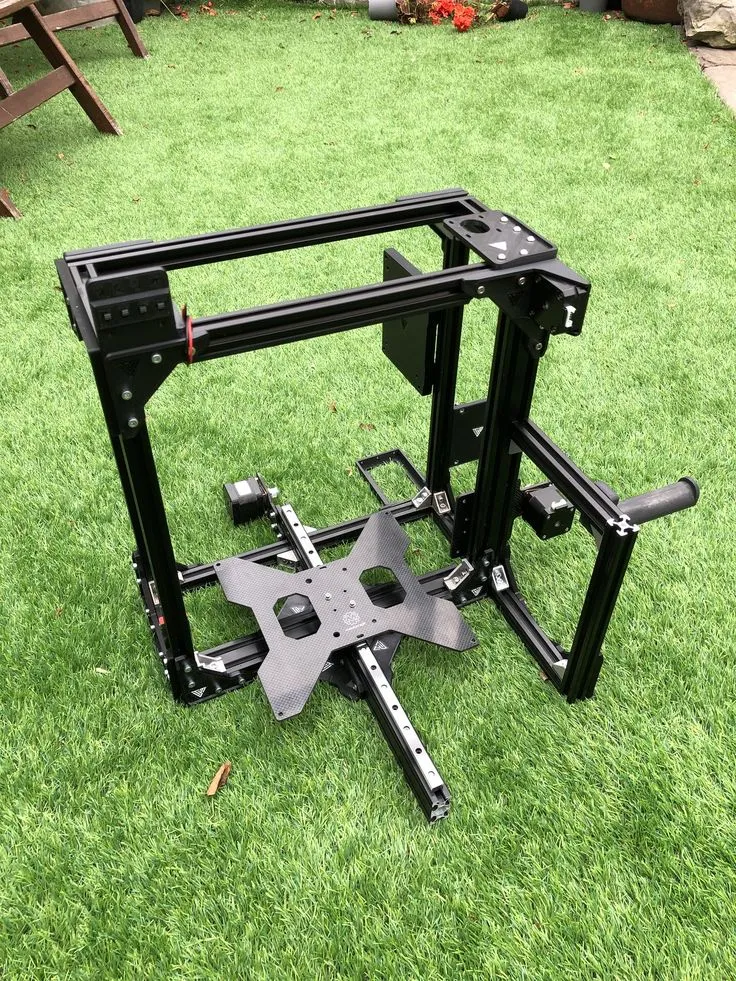

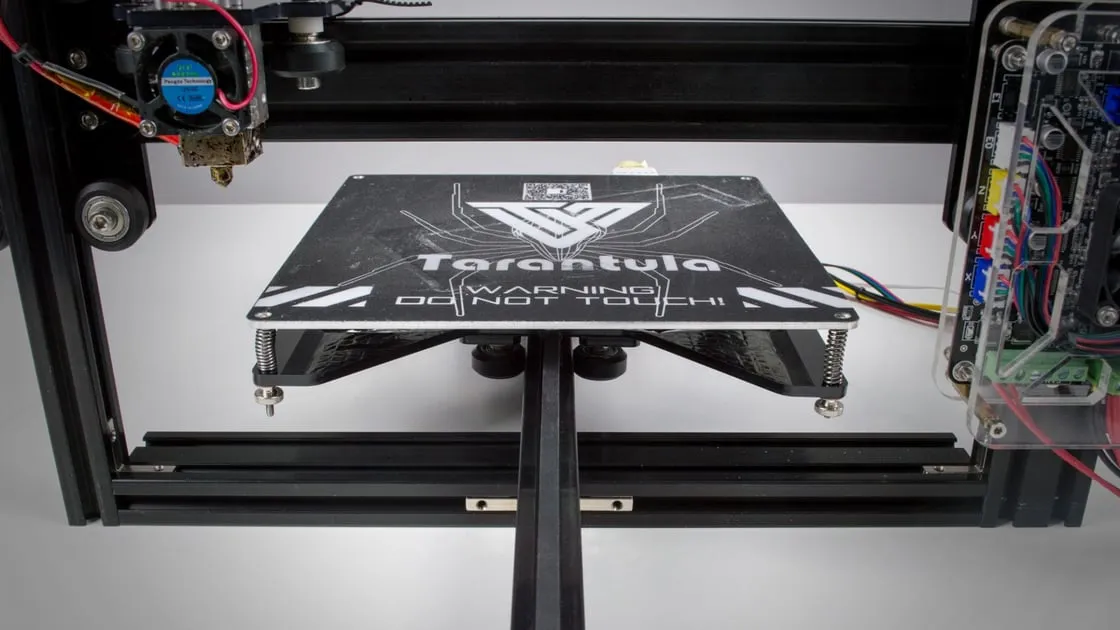

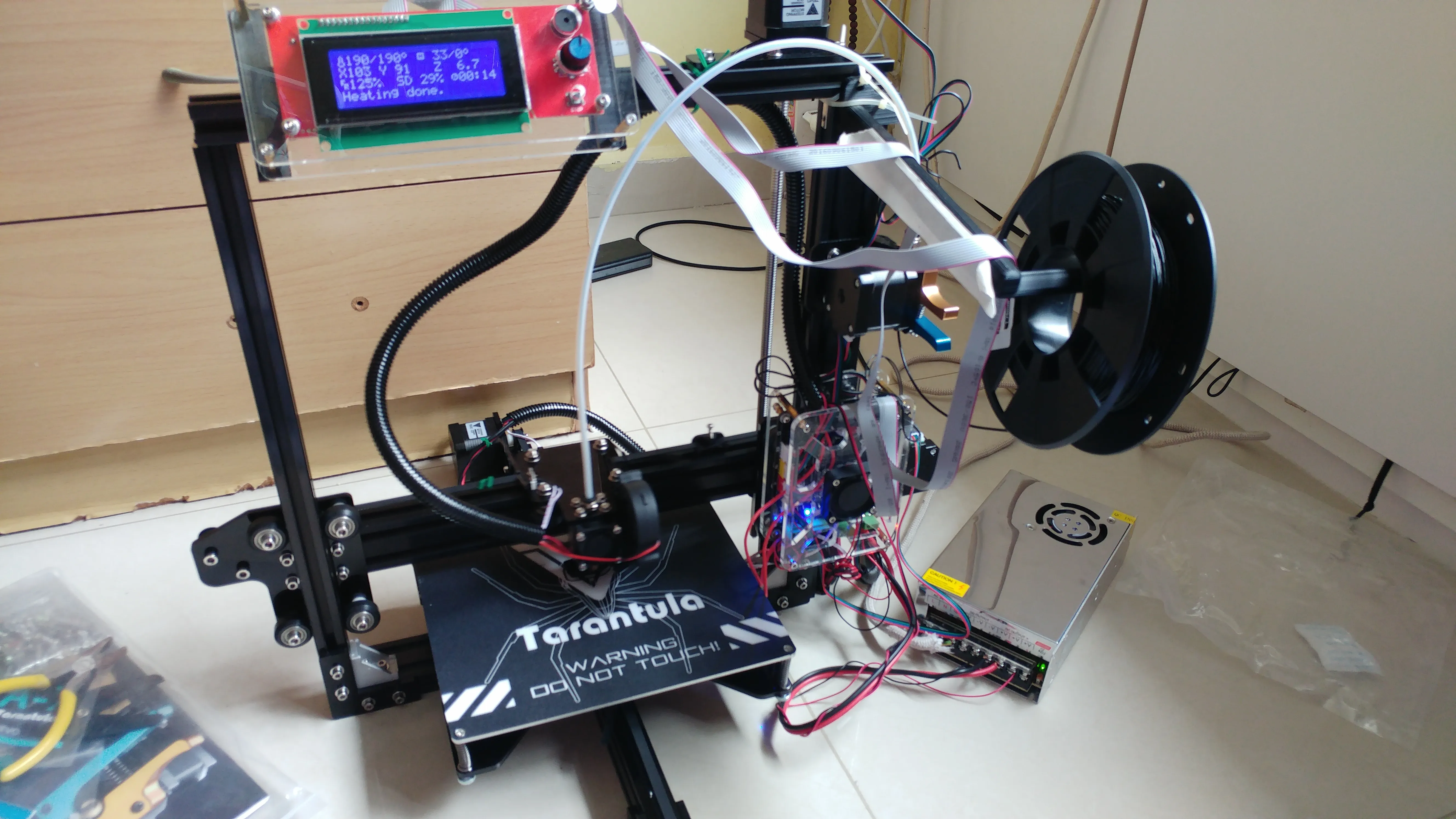

The Tevo Tarantula is a popular and affordable 3D printer known for its ease of use and upgrade potential. To truly unlock its printing speed potential and quality, you need to understand and optimize its acceleration settings. These settings control how quickly the printer’s print head and bed move, directly influencing print time and the quality of your finished prints. Proper configuration of these settings will allow you to balance speed and precision, getting the most out of your Tevo Tarantula. This guide will walk you through the crucial acceleration settings and how to optimize them for faster and better prints. By making some adjustments to the firmware and slicer software, you can drastically improve your printing results.

What are Acceleration Settings?

Acceleration settings dictate how rapidly the printer’s print head and bed can change their speed during movement. Think of it like a car; a higher acceleration allows the car to go from 0 to 60 mph much faster. In 3D printing, the acceleration value determines how rapidly the printer can change its speed along the X, Y, and Z axes, as well as the speed of extrusion. These settings are measured in millimeters per second squared (mm/s²). They are controlled through the printer’s firmware (like Marlin) and further adjusted through your slicer software such as Cura or Simplify3D. Adjusting these settings correctly is pivotal to achieving the best balance between print speed and overall print quality on your Tevo Tarantula.

Why Acceleration Matters for 3D Printing

Acceleration settings significantly impact both the speed and quality of your 3D prints. Faster acceleration allows for quicker movements, thus reducing print times. However, excessively high acceleration can lead to issues like ringing, vibrations, and reduced print quality. Conversely, slow acceleration results in slower prints. The goal is to find the optimal balance. By fine-tuning these parameters, you can significantly reduce the overall print time without sacrificing the finer details of your 3D models. It is a critical aspect of 3D printing optimization, providing a pathway to faster and more efficient production of printed parts. Proper acceleration tuning optimizes both the efficiency and visual aspects of 3D-printed objects.

How Acceleration Affects Print Quality

The settings greatly influence print quality. High acceleration values can cause the printer’s frame to vibrate, leading to ringing artifacts, where ripples appear on the print’s surface. This is especially noticeable on sharp corners and changes in direction. Low acceleration settings, on the other hand, can result in rounded corners and slower overall print speeds. Optimizing acceleration settings helps minimize these issues. The correct settings ensure that the printer’s movements are precise and controlled, leading to cleaner lines, sharper details, and improved overall aesthetics of your prints. Fine-tuning these settings is crucial for achieving the desired print quality, especially when printing complex geometries or highly detailed models. Understanding this direct link between acceleration and print quality will allow you to dial in the best settings for your Tevo Tarantula.

Top 5 Acceleration Settings for Tevo Tarantula

Here are the top 5 crucial acceleration settings you should adjust for optimal print performance on your Tevo Tarantula. These adjustments, a combination of printer firmware and slicer settings, will greatly improve both print speed and quality. Each setting contributes in its own way to the overall performance of the printer. Remember that experimentation and test prints are key to finding the perfect settings for your specific setup and the types of materials you use. Always save your original settings before making adjustments, so you can revert back if necessary. It is important to iteratively refine these values for the best results.

Setting 1: Acceleration for X and Y Axis

The acceleration settings for the X and Y axes control the speed at which the print head moves horizontally. These settings directly affect the speed at which the printer can traverse the print bed and move along the horizontal plane. Increase these values to speed up prints. However, excessively high values can cause vibrations and ringing effects. This is where balance is critical. Start with the default settings in your firmware and gradually increase them, testing with small prints to see how the quality is affected. Consider the weight of your print head and the overall rigidity of your printer’s frame. More robust setups can typically handle higher acceleration values.

Optimal Values and Adjustments

A good starting point for the X and Y axis acceleration on a Tevo Tarantula is typically between 800 mm/s² and 1500 mm/s². However, this can vary based on your printer’s modifications and build quality. If you have upgraded components like a stiffer frame, you might be able to push the acceleration values higher. Begin with a value in the lower range, and slowly increase it, observing the print quality after each adjustment. For precise adjustments, use test prints featuring sharp corners and small details. These prints will quickly reveal any ringing or other artifacts caused by excessive acceleration. Use a test cube or a similar model to evaluate your prints.

Setting 2: Jerk Control

Jerk control determines the maximum instantaneous speed change that the printer is allowed to make. Essentially, it limits how abruptly the print head can change direction. This setting is separate from acceleration but also crucial for managing print quality, particularly at corners and direction changes. Jerk settings prevent the printer from making abrupt stops and starts, reducing vibrations and ringing. Proper adjustment of jerk settings can greatly improve the surface finish of your prints. Jerk control interacts with acceleration, so consider both settings when optimizing your print speed and quality.

Understanding Jerk and Its Impact

Jerk settings have a significant effect on how smooth and accurate your prints will be. A high jerk setting can cause the printer to make abrupt changes in direction, leading to vibrations and, consequently, poor print quality. Lower jerk settings smooth out these transitions, resulting in more uniform and refined prints. However, too low a jerk setting can slow down the printer unnecessarily, especially on small, detailed prints where many direction changes occur. Jerk settings thus directly affect print speed and quality, making them critical for optimization. The optimal value strikes a perfect balance between print speed and surface finish.

Recommended Jerk Settings

For the Tevo Tarantula, a good starting point for jerk settings is typically around 10 mm/s to 20 mm/s for the X and Y axes. For the Z axis, it is often set significantly lower, usually between 0.4 mm/s and 0.6 mm/s. These are good starting points, but your actual settings may vary based on your printer’s configuration, materials, and upgrades. Start with the lower values and increase them gradually, observing the print quality at corners and edges. When testing jerk settings, pay close attention to the corners of your prints. Excessive jerk will cause ringing effects, while insufficient jerk can round off corners, diminishing the sharpness of the print. Test prints featuring a combination of sharp angles and smooth curves are very helpful for jerk setting calibration.

Setting 3: Acceleration for Z-Axis

The Z-axis acceleration controls the vertical movement of the print bed or the print head (depending on your printer’s configuration). While Z-axis acceleration doesn’t directly affect print speed in the same way as X and Y, it does influence the time taken to move between layers. An appropriate Z-axis acceleration setting can reduce the overall print time, particularly for taller models. However, excessive Z-axis acceleration can lead to layer shifting, as the printer’s movement might be too abrupt for the bed to keep up, resulting in misalignment of the layers. The Z-axis acceleration setting needs to be balanced between speed and precision.

Balancing Speed and Precision

The optimal Z-axis acceleration depends on the printer’s mechanical components and build quality. For the Tevo Tarantula, a good starting point is typically between 100 mm/s² and 400 mm/s². However, it is usually more dependent on your bed’s mechanism. Start at the lower end and increase gradually, monitoring for any layer shifting or other signs of instability. The Z-axis acceleration setting does not influence speed as much as the X and Y settings. The goal is to optimize the layer change time without affecting the print’s overall quality. Fine-tuning the Z-axis acceleration helps improve the printing time and the quality of the vertical surfaces.

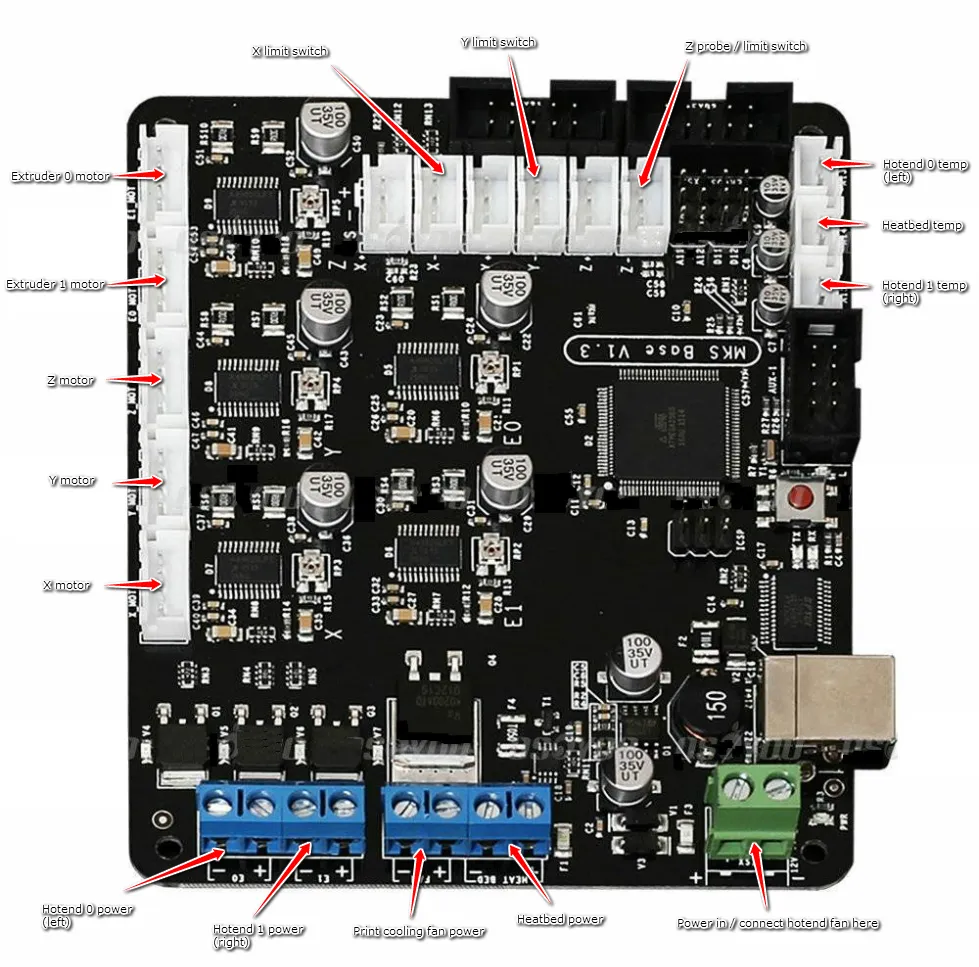

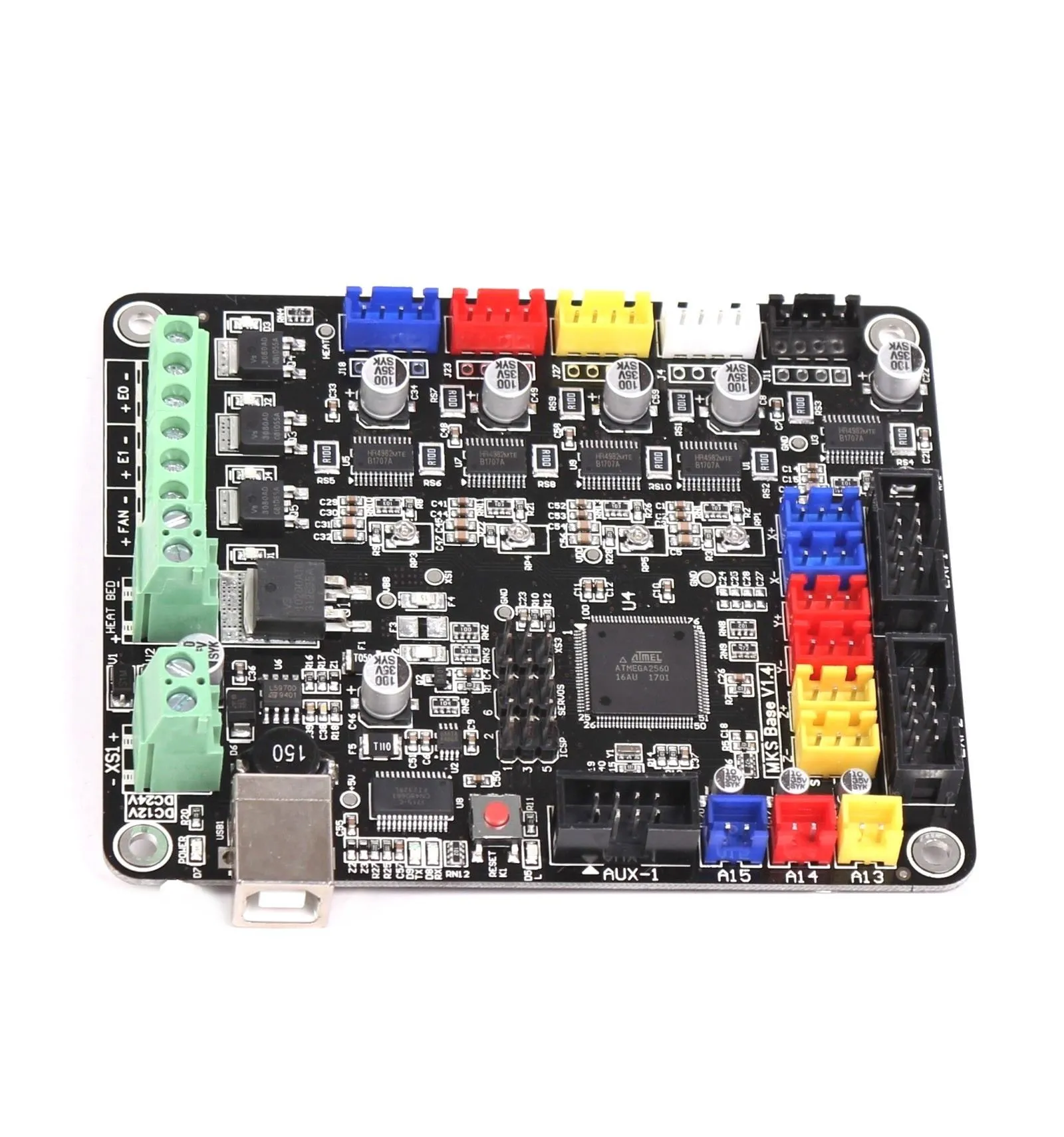

Setting 4: Firmware and Slicer Configuration

Both the printer’s firmware (like Marlin) and your slicer software (like Cura or Simplify3D) are essential for setting and controlling acceleration. The firmware provides the base settings, while the slicer software allows for more granular control, especially when generating the G-code instructions for your prints. You typically set the maximum acceleration values in the firmware. These are like the “ceiling” values; your slicer software then tells the printer how to use these settings during the print process. Correct configuration of both firmware and the slicer is crucial for realizing the full potential of your printer’s acceleration settings.

Cura and Simplify3D Acceleration Settings

In slicers such as Cura and Simplify3D, you can fine-tune various acceleration settings. Typically, you’ll find these under the ‘Speed’ or ‘Acceleration Control’ sections of the settings menu. Cura often allows you to set acceleration for different parts of the print, such as inner walls, outer walls, and infill. This allows you to optimize the settings for various printing situations. Simplify3D provides similar controls, offering options to set distinct acceleration values for different features and material types. Experimenting with these settings in your slicer can help you dial in optimal performance. Test prints are essential to assess the results of changes.

Setting 5: Retraction Settings and Acceleration

Retraction settings, though not directly related to acceleration, can indirectly affect print speed and quality. Retraction controls how much filament is pulled back from the nozzle and how quickly this action occurs. If retraction settings are not optimized, you might encounter issues like stringing or oozing, which can affect the overall print quality. The retraction acceleration setting helps to control how quickly the filament is retracted. By carefully tuning the retraction settings along with acceleration settings, you can improve the print quality and potentially even increase the print speed. Retraction helps in creating cleaner prints and plays an important role in the accuracy of the model.

Impact of Retraction on Print Speed

When the print head moves from one area to another, the retraction setting can impact the time of this movement. By using the correct retraction settings, you can reduce the stringing and oozing of the material, hence improving the quality. Adjusting the retraction distance and speed will influence the quality of the final output. In terms of acceleration, faster retraction speeds (higher retraction acceleration) can help prevent stringing and improve print quality. However, excessively high retraction acceleration can cause other issues, such as grinding of the filament or even clogging the nozzle. It is important to find a balance that works best for the material you are using and your print setup. Test prints are vital in finding the appropriate settings.

Troubleshooting Common Print Issues

Understanding and troubleshooting the issues that can arise from incorrect acceleration settings is vital. Identifying these problems early and adjusting your settings accordingly can save you time and filament. Common issues include ringing, vibrations, layer shifting, and poor surface finishes. By understanding the causes and effects of each issue, you can make informed decisions about adjusting your acceleration settings to optimize the print results. Proper troubleshooting helps fine-tune your printer to achieve the best balance between speed and quality. The main goal is to produce high-quality prints consistently.

Over-Acceleration Artifacts

Over-acceleration occurs when the printer’s movement is too aggressive, leading to artifacts such as ringing or ghosting. Ringing manifests as ripples or waves on the print’s surface, particularly around sharp corners and features. This is due to vibrations in the printer’s frame. If you observe ringing, it is often a sign that your acceleration or jerk settings are too high. Reducing these values can usually resolve the issue. Other indicators of over-acceleration include layer shifting and a general reduction in print quality, especially in fine details. You may need to reduce the acceleration values to eliminate these artifacts.

Under-Acceleration Issues

Under-acceleration causes a different set of problems. The printer may move too slowly, resulting in rounded corners, a loss of fine details, and potentially increased print times. The overall print quality may be poor. Low acceleration settings prevent the printer from reaching its full potential. If you’re experiencing these issues, carefully increase your acceleration values to find the optimal settings for your printer. The best approach is incremental adjustments, coupled with careful testing. Under-acceleration usually doesn’t cause structural damage but it greatly reduces the overall quality and accuracy of the prints. Finding the right balance is key.

Best Practices for Acceleration Tuning

Following best practices for acceleration tuning can ensure you get the best possible results from your Tevo Tarantula. This includes using test prints, monitoring your printer’s behavior, and regularly calibrating settings. Experimentation and iterative improvement are vital. By applying these best practices, you can optimize the print speed and produce high-quality prints. Regular maintenance, combined with diligent testing, allows you to keep your printer performing at its best. Be consistent with your testing, and take the time to refine your settings.

Test Prints and Iteration

The most effective way to optimize acceleration settings is through test prints and iteration. Start with the default settings for your Tevo Tarantula and then make small adjustments, such as increasing the acceleration values gradually. Print test models that incorporate a variety of features, including sharp corners, overhangs, and fine details. After each adjustment, observe the print quality, paying close attention to any artifacts, such as ringing or rounding of corners. Based on the results, make further adjustments until you achieve a good balance between speed and print quality. Repeat this process until you find the settings that yield the best results. Small test prints that only take a few minutes are very useful here.

Monitoring Your Printer

Regular monitoring is crucial for maintaining optimal print quality and identifying any potential problems. During a print, watch and listen to your printer. If you notice any unusual vibrations, or if the print quality begins to decline, stop the print and review your acceleration settings. Keeping a log of your settings and the corresponding print results will help you track your progress and identify trends. Monitoring also involves regularly checking the mechanical components of your printer to ensure they are in good working order. Proper monitoring helps maintain consistent performance and ensures that you can quickly identify and address issues as they arise, helping to reduce wasted filament and improve your overall printing experience. Watch out for any unusual sounds or movements.

Resources and Further Learning

There is a wealth of resources available to help you further refine your 3D printing knowledge. Online forums, such as those on Reddit and other 3D printing communities, provide a great place to ask questions and share your experiences. YouTube channels dedicated to 3D printing offer video tutorials. Experiment with different filaments and settings to discover how they affect the results. Continuing your education will help you keep improving your 3D printing skills. Join the online community and share experiences and results for a better understanding.